Single-Pair Ethernet PCB

Automotive

Single Pair Ethernet

The CAN vehicle bus has been the industry standard for signal collection from sensors and actuators in vehicles. However, with a limited bandwidth of just 1 Mbps, it no longer meets the demands of modern software-defined vehicles (SDVs), which require high-speed, low-latency data exchange for advanced functions like ADAS, over-the-air updates, and real-time diagnostics.

Beyond networking challenges, OEMs struggle with supplier dependency. Critical E/E components—such as sensors, actuators, and ECUs—are tightly integrated into the vehicle architecture, making replacements or upgrades a costly and time-intensive process. The firmware of these components is deeply embedded within the overall vehicle software stack, meaning that changing a single component often requires extensive rework across multiple ECUs, including hardware compatibility adjustments and firmware updates.

Solution

To overcome the limitations of traditional in-vehicle networking, 10BASE-T1S provides the missing link in the automotive Ethernet ecosystem. Unlike CAN, 10BASE-T1S enables true Ethernet-to-the-edge connectivity, supporting modern zonal architectures with higher flexibility, increased bandwidth efficiency, and seamless integration into existing Ethernet infrastructures. By eliminating the need for protocol translation between CAN and Ethernet, 10BASE-T1S reduces system complexity, lowers costs, and enhances scalability. This is also enabled by the multi-drop nature of 10BASE-T1S, which drastically simplifies the wiring harness.

In terms of the firmware, an abstraction layer between the E/E components and ECUs is introduced to combat the problem of the supplier dependency of OEMs. By leveraging Zephyr as the real-time operating system, a more flexible and modular approach to firmware development is enabled, providing key advantages:

- Flexible PCB pin definitions – Enabling easy interchangeability of sensors, actuators, and other E/E components

- Standardized APIs – Reducing dependency on proprietary firmware and simplifying software integration

- Modular driver development – Ensuring compatibility with a wide range of

Technologies Used

- Single-Pair Ethernet - 10BASE-T1S

- Zephyr

- Automotive-grade components

- ILaS and ISELED

Highlights of the Project

- Leveraging 10BASE-T1S (and other single-pair Ethernet) for simpler integration into the vehicle for high bandwidth use cases - Based on the LAN8670 or NCN26010

- Development of PCB prototypes with currently used E/E-components (such as UWB, ILaS & ISELED, etc.) with a 10BASE-T1S as the communication interface

- Controlling LEDs with ILaS using the ATSAME54

- Firmware development leveraging Zephyr RTOSs

- Easy integration of new components and hardware

- The modular development approach and abstraction layer reduce the board bring-up and testing time

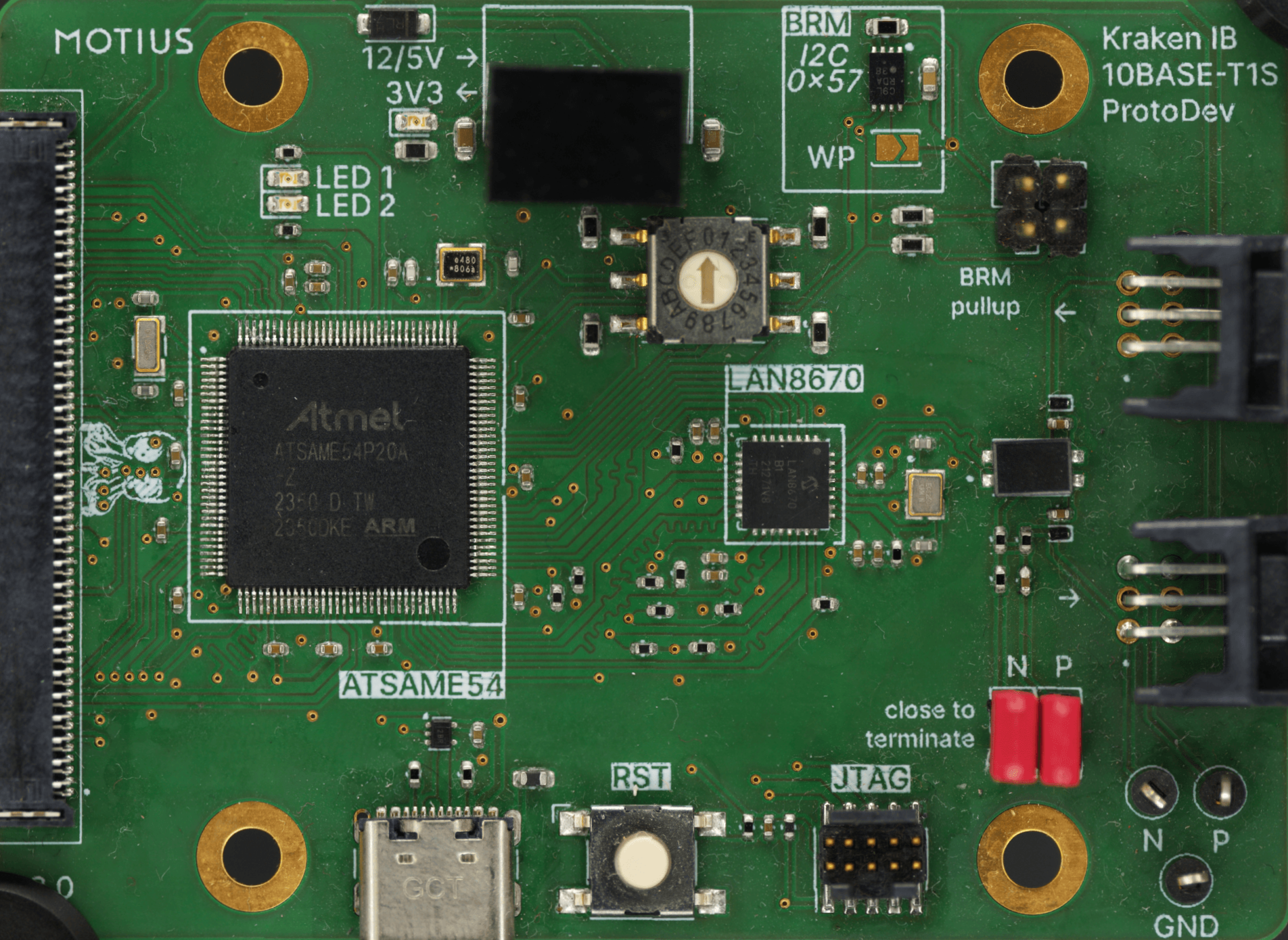

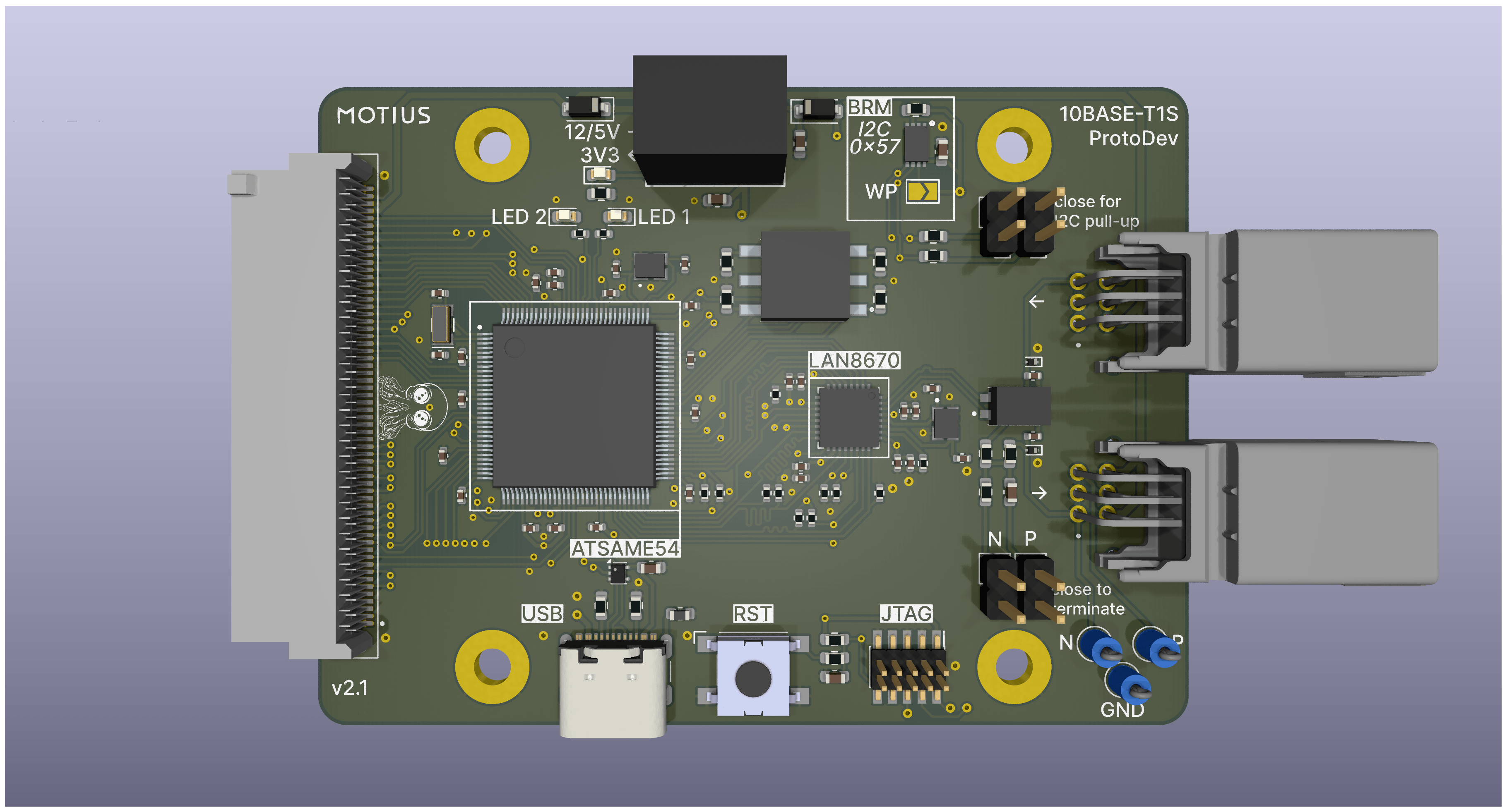

PCB with the microcontroller and 10BASE-T1S PHY. The microcontroller acts as an abstraction layer the the peripherals connected to the left side connector

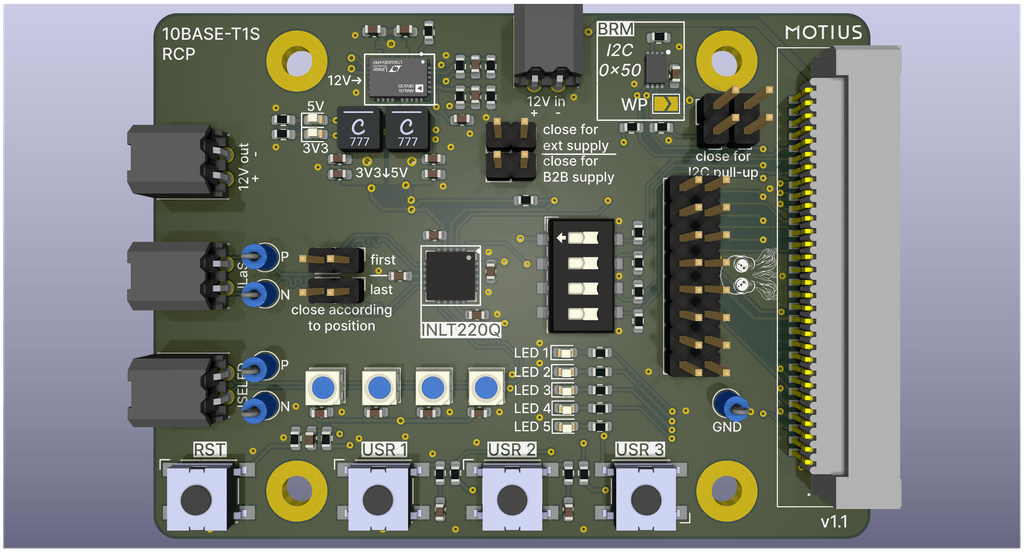

PCB with the "target" device, in this case a ILaS driver IC and ISELED LEDs

Application at Your Company

Motius can support Your Company in the development of new E/E components, using modern embedded system development practices and technologies such as Zephyr, RISC-V, and Single Pair Ethernet.