Ultrasonic AI

Aerospace

Ultrasonic Inspection

We successfully implemented an automated QA solution using ultrasonic sensors, resulting in:

- Significant reduction in manual inspection errors through AI-based ultrasonic inspection

- Enhanced detection of internal segregations, reducing throw-away rate

- Improved operational efficiency by automating and optimizing the inspection process

Approach

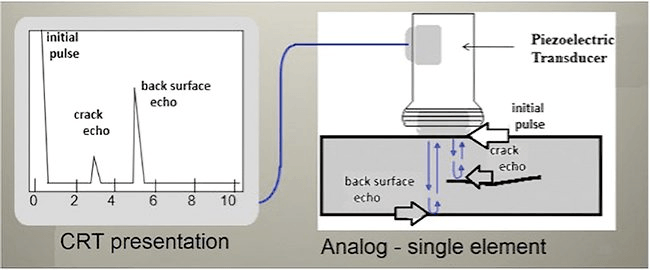

- MTU needed to ensure quality of critical engine components made from high-performance alloys

- Manual inspection only assessed surface-level defects; internal defects went undetected, leading to high discard rates and increased costs

- To solve this, an AI-driven ultrasonic inspection system was developed

- This system improved detection of internal segregations and increased efficiency in the QA process

Technologies

- TensorFlow

- Deep Learning

- Sound Classification

Extending QA with 3D Defect Annotation

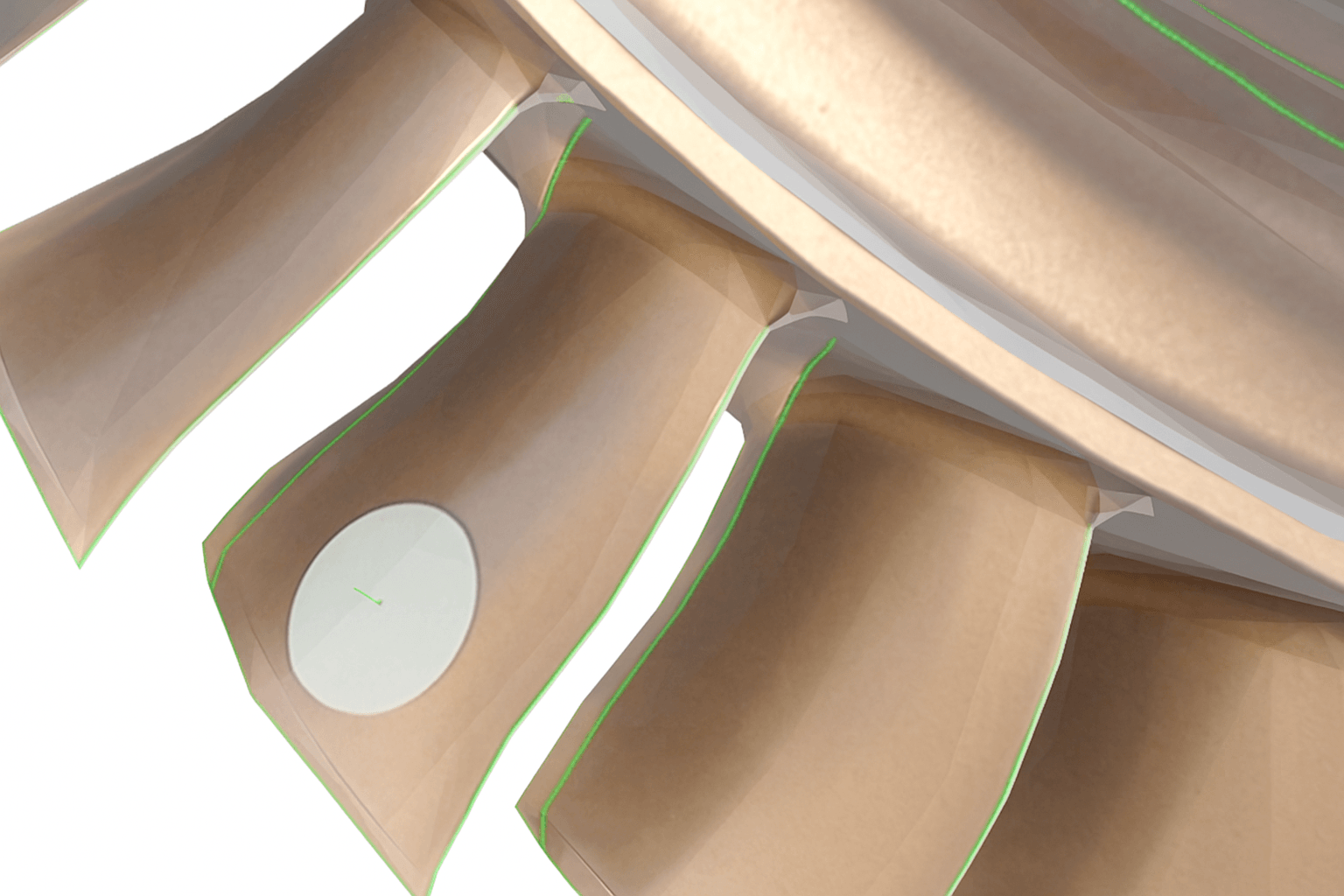

Further improving defect detection, we created a prototype that used VisionLib to track parts and enabled precise point-marking on these components. The parts are matched with a 3D virtual model in real time, which allows workers to make annotations on specific parts and defects.

- Augmented Reality Application to mark defects

- Object tracking also works for rotational symmetric parts

- High accuracy performance in early stage

Result

Using an AR solution to align CAD models with real-world turbine components, we eliminated manual measurement and documentation by enabling users to mark defects directly in the CAD model.

- Faster processing

- More comprehensive information gathering

- In-depth defect data analysis